Innovating

Precision Technology,

Innovating

Precision Technology,

精密技術創新,驅動跨界發展。

精密技術創新,

驅動跨界發展。

精密技術創新,

驅動跨界發展。

Leading Global Impact.

Leading

Global Impact.

Leading

Global Impact.

About Glonius

About Glonius

擁有深厚製造底蘊,打造精準解決方案

擁有深厚製造底蘊

打造精準解決方案

擁有深厚製造底蘊

打造精準解決方案

With deep manufacturing heritage,

delivering precise solutions

With deep manufacturing heritage,

delivering precise solutions

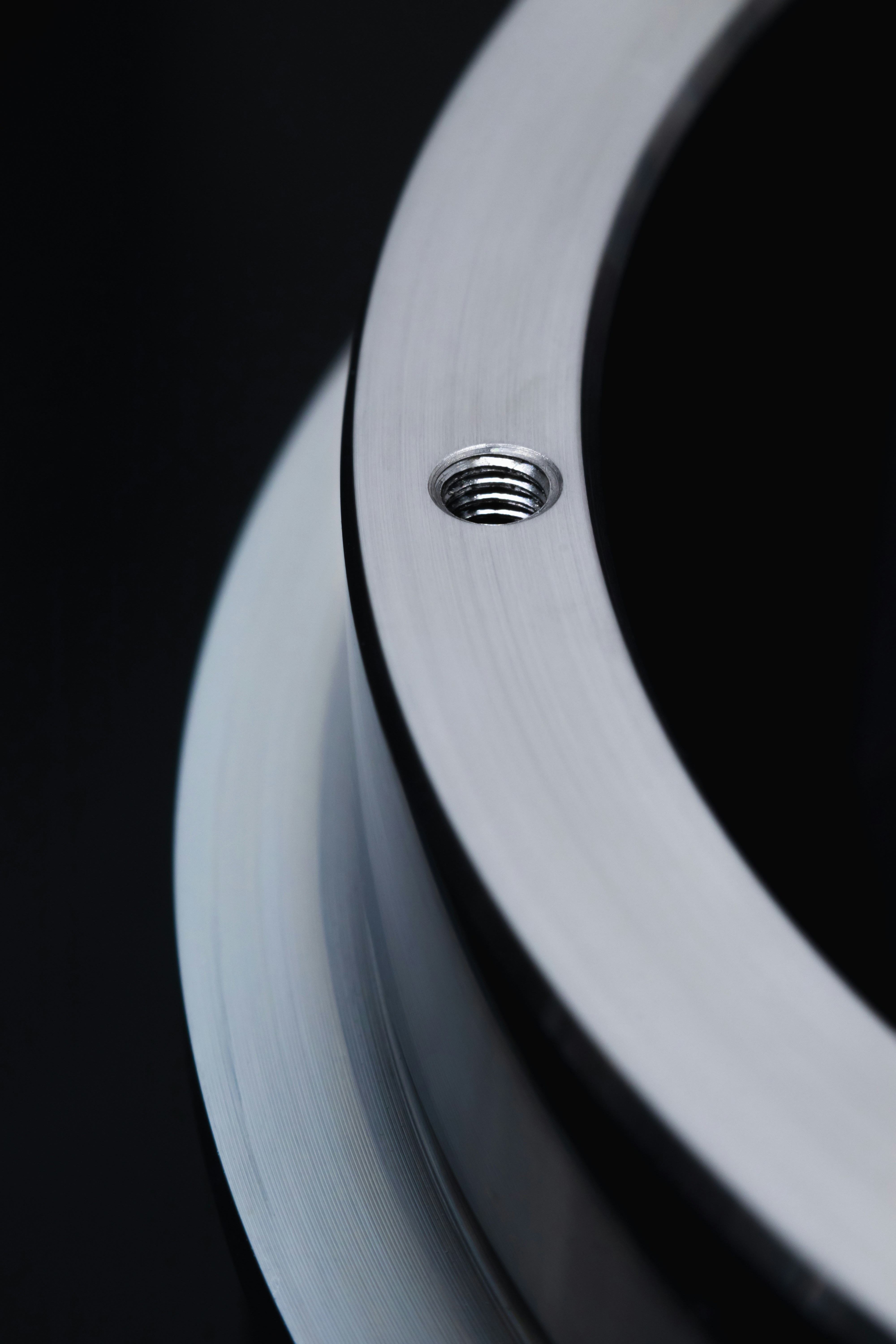

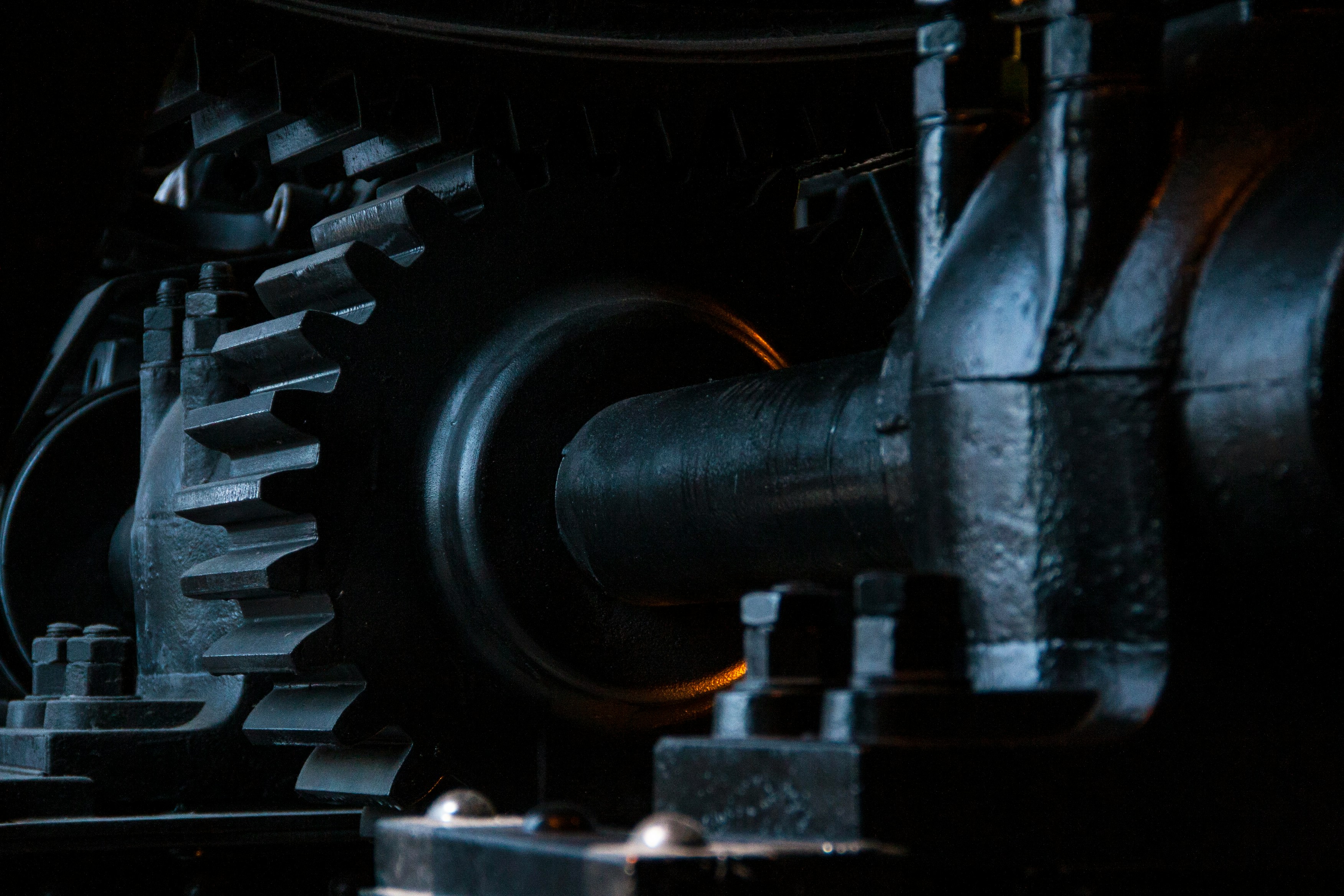

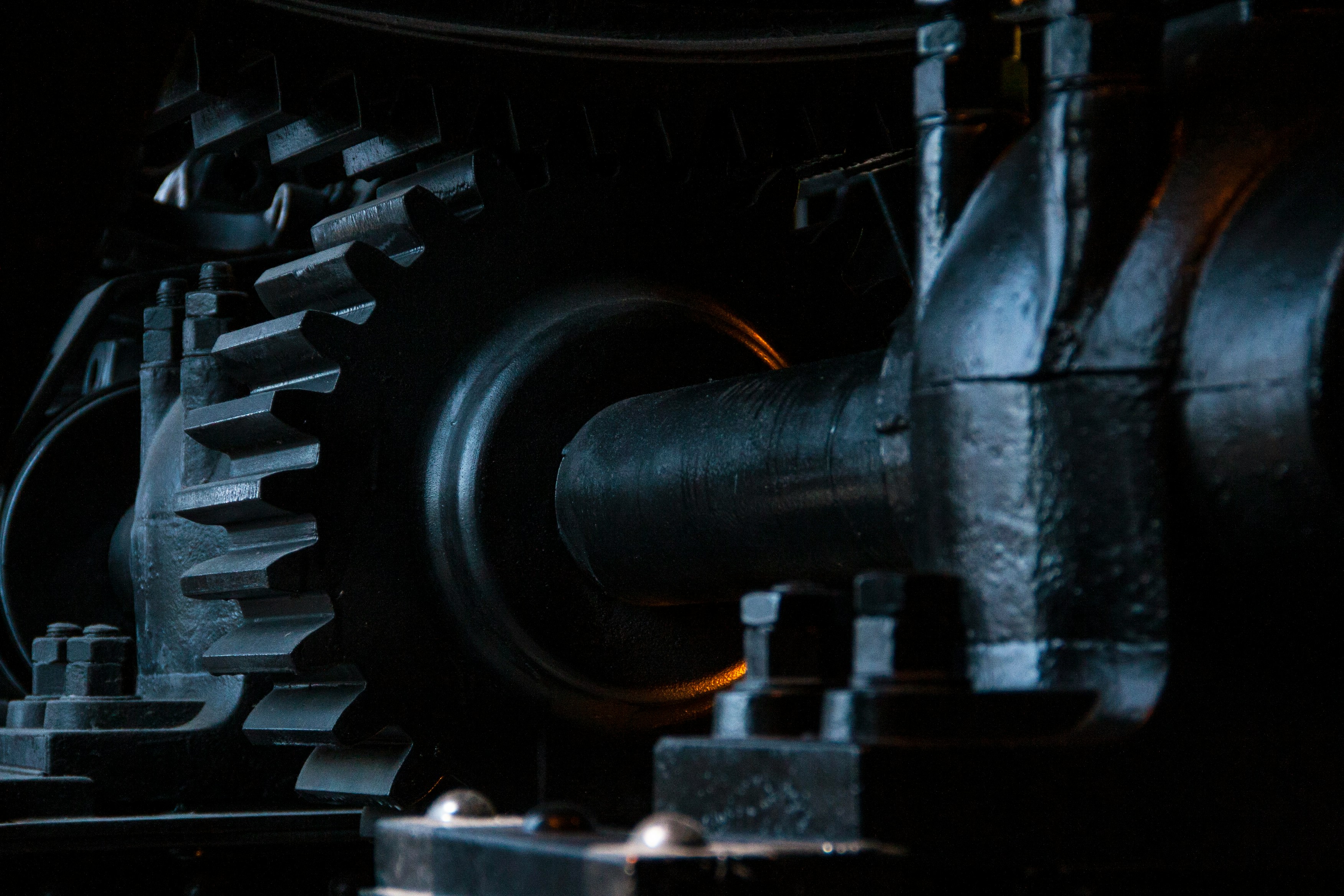

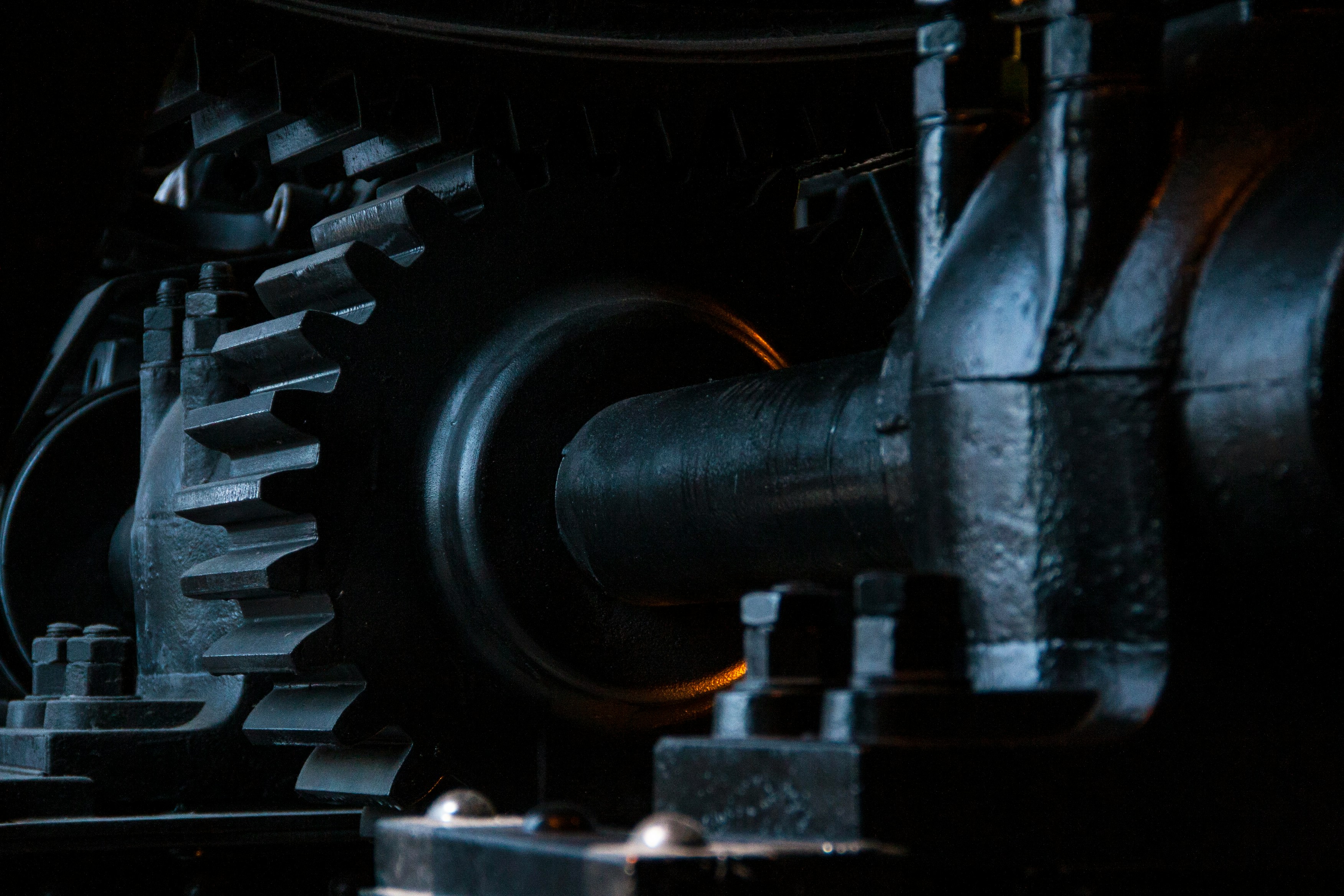

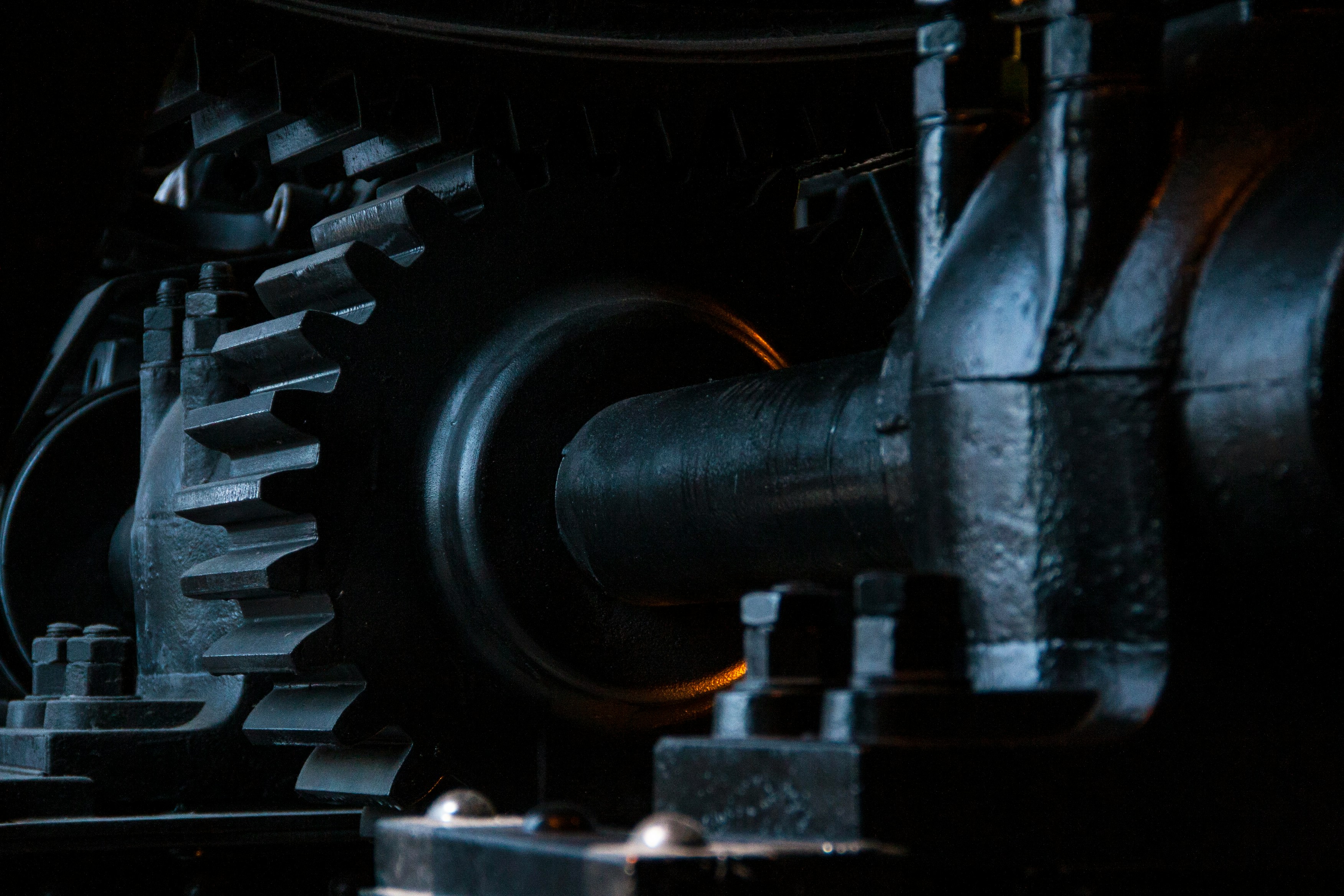

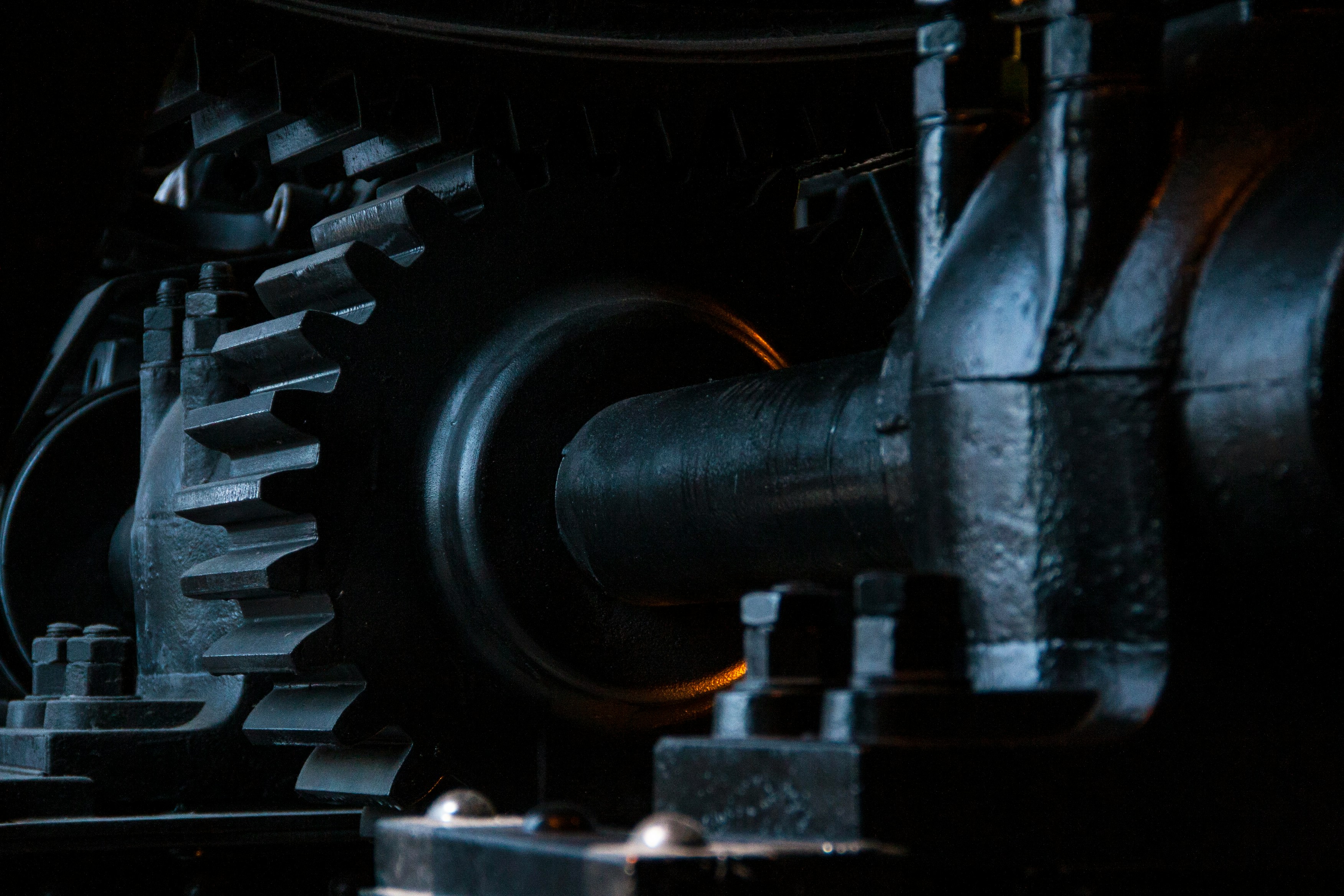

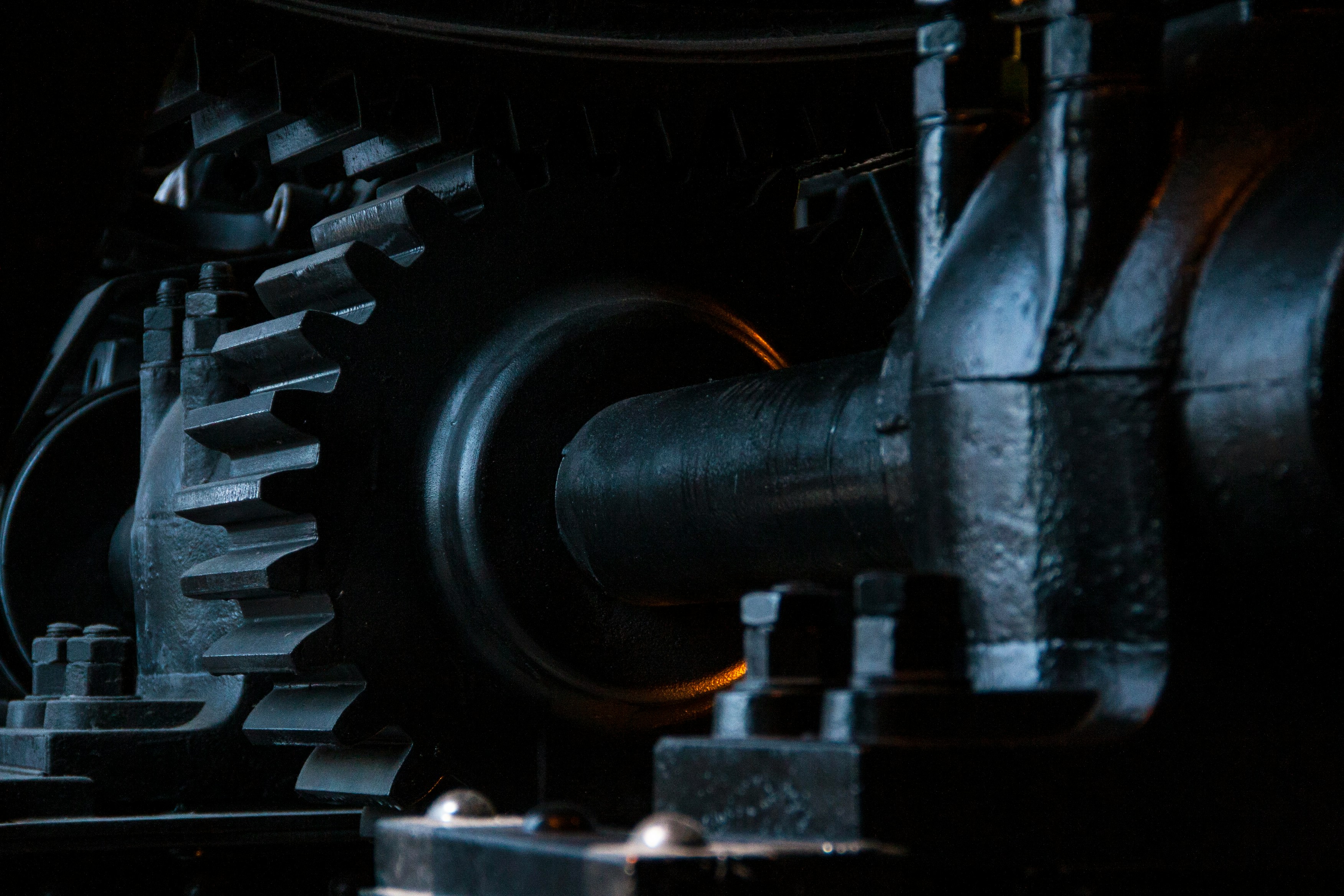

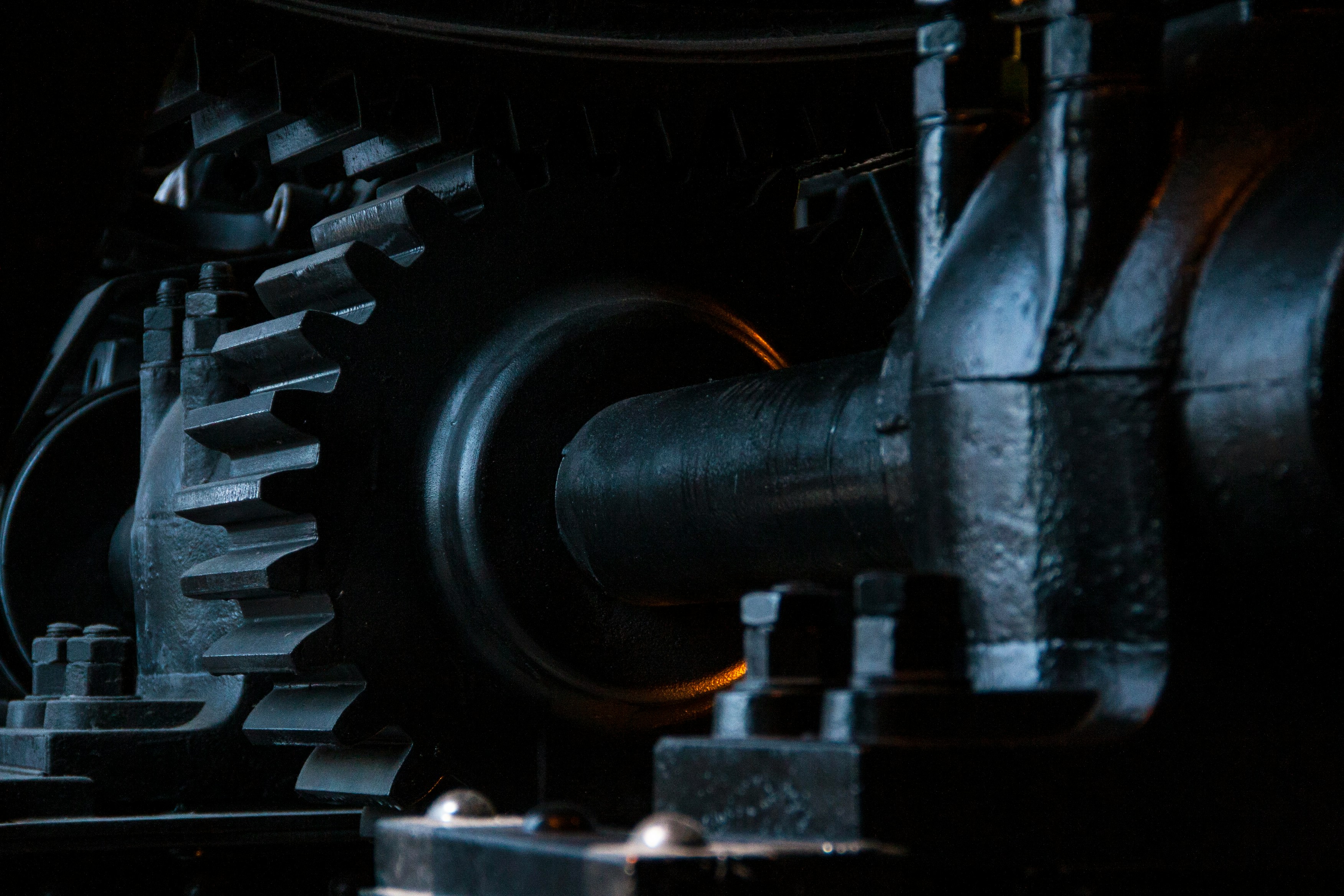

國星是一間專注於精密技術整合的設計公司,起源於擁有近60年精密齒輪製造經驗的禾致動力科技有限公司。

從傳統製造產業中走來,以豐富的實務經驗為基礎,能夠從製造角度深度理解客戶需求,確保每個設計方案都具備實際可行性。

致力於透過技術整合與創新設計,為客戶提供精準且高效的解決方案。

從初期構想到最終量產,不僅是技術供應商,更是與您並肩作戰的開發夥伴,協助將每一個創新想法轉化為現實。

國星是一間專注於精密技術整合的設計公司,起源於擁有近60年精密齒輪製造經驗的禾致動力科技有限公司。

從傳統製造產業中走來,以豐富的實務經驗為基礎,能夠從製造角度深度理解客戶需求,確保每個設計方案都具備實際可行性。

致力於透過技術整合與創新設計,為客戶提供精準且高效的解決方案。

從初期構想到最終量產,不僅是技術供應商,更是與您並肩作戰的開發夥伴,

協助將每一個創新想法轉化為現實。

國星是一間專注於精密技術整合的設計公司,

起源於擁有近60年精密齒輪製造經驗的禾致動力科技有限公司。

從傳統製造產業中走來,以豐富的實務經驗為基礎,

能夠從製造角度深度理解客戶需求,確保每個設計方案都具備實際可行性。

致力於透過技術整合與創新設計,為客戶提供精準且高效的解決方案。

從初期構想到最終量產,不僅是技術供應商,更是與您並肩作戰的開發夥伴,

協助將每一個創新想法轉化為現實。

Glonius is a design company specializing in precision technology integration, originating from Global Gear Industry with nearly 60 years of precision gear manufacturing experience. Coming from traditional manufacturing industry, we leverage our rich practical experience to deeply understand client needs from a manufacturing perspective, ensuring every design solution is practically feasible.

We are committed to providing precise and efficient solutions through technology integration and innovative design. From initial concepts to final mass production, we are not just technology providers, but development partners working alongside you to transform every innovative idea into reality.

Glonius is a design company specializing in precision technology integration, originating from Global Gear Industry with nearly 60 years of precision gear manufacturing experience. Coming from traditional manufacturing industry, we leverage our rich practical experience to deeply understand client needs from a manufacturing perspective, ensuring every design solution is practically feasible.

We are committed to providing precise and efficient solutions through technology integration and innovative design. From initial concepts to final mass production, we are not just technology providers, but development partners working alongside you to transform every innovative idea into reality.

Our values

Our values

Our values

從概念到量產,我們陪您走完每一步

從概念到量產,

陪您走完每一步

從概念到量產,

我們陪您走完每一步

From Concept to Production,

We're With You Every Step.

From Concept to Production,

We're With You Every Step.

我們相信,好的設計來自於深度理解客戶需求與製造現實。

我們憑藉豐富的製造經驗,結合技術專業與設計創新,

成為您值得信賴的開發夥伴,為您提供從概念到量產的完整解決方案。

我們相信,好的設計來自於深度理解客戶需求與製造現實。

我們憑藉豐富的製造經驗,結合技術專業與設計創新,成為您值得信賴的開發夥伴,為您提供從概念到量產的完整解決方案。

We believe great design comes from deeply understanding client needs and manufacturing realities.

With extensive manufacturing experience, we combine technical expertise with design innovation to become your trusted development partner, delivering complete solutions from concept to mass production.

We believe great design comes from deeply understanding client needs and manufacturing realities.

With extensive manufacturing experience, we combine technical expertise with design innovation to become your trusted development partner, delivering complete solutions from concept to mass production.

We believe great design comes from deeply understanding client needs and manufacturing realities. With extensive manufacturing experience,

we combine technical expertise with design innovation to become your trusted development partner,

delivering complete solutions from concept to mass production.

0

0

實現導向

Feasibility Focused

深入了解設計細節,確保方案能順利製造且具成本效益

Understanding design details to ensure solutions are manufacturable and cost-effective.

0

0

實現導向

Feasibility Focused

深入了解設計細節, 確保方案能順利製造 且具成本效益

Understanding design details to ensure solutions are manufacturable and cost-effective.

0

0

實現導向

Feasibility Focused

深入了解設計細節,確保方案能順利製造且具成本效益

Understanding design details to ensure solutions are manufacturable and cost-effective.

0

0

優化思維

Optimization Driven

從實際問題出發,提出可執行的改善與優化方案

Starting from real problems to propose actionable improvements and optimization solutions

0

0

優化思維

Optimization Driven

從實際問題出發, 提出可執行的改善與優化方案

Starting from real problems to propose actionable improvements and optimization solutions

0

0

優化思維

Optimization Driven

從實際問題出發,提出可執行的改善與優化方案

Starting from real problems to propose actionable improvements and optimization solutions

0

0

技術整合

Technology Integration

技術與設計並行,決策更有精度與深度。

Technology and design work together, ensuring precise execution with strategic depth

0

0

技術整合

Technology Integration

技術與設計並行,決策更有精度與深度。

Technology and design work together, ensuring precise execution with strategic depth

0

0

技術整合

Technology Integration

技術與設計並行,決策更有精度與深度。

Technology and design work together, ensuring precise execution with strategic depth

0

0

共創合作

Collaborative Partnership

與客戶密切協作,確保方案符合實際應用需求。

Working closely with clients to ensure solutions meet real-world application needs

0

0

共創合作

Collaborative Partnership

與客戶密切協作,確保方案符合實際應用需求。

Working closely with clients to ensure solutions meet real-world application needs

0

0

共創合作

Collaborative Partnership

與客戶密切協作,確保方案符合實際應用需求。

Working closely with clients to ensure solutions meet real-world application needs

Case Studies

Case Studies

Case Studies

了解我們如何協助客戶解決挑戰,

實現創新突破

了解我們如何

協助客戶解決挑戰,實現創新突破

Discover how we help clients

solve challenges and achieve innovative breakthroughs

Discover how we

help clients solve challenges and achieve innovative breakthroughs

設備異音問題

Equipment Noise Issues

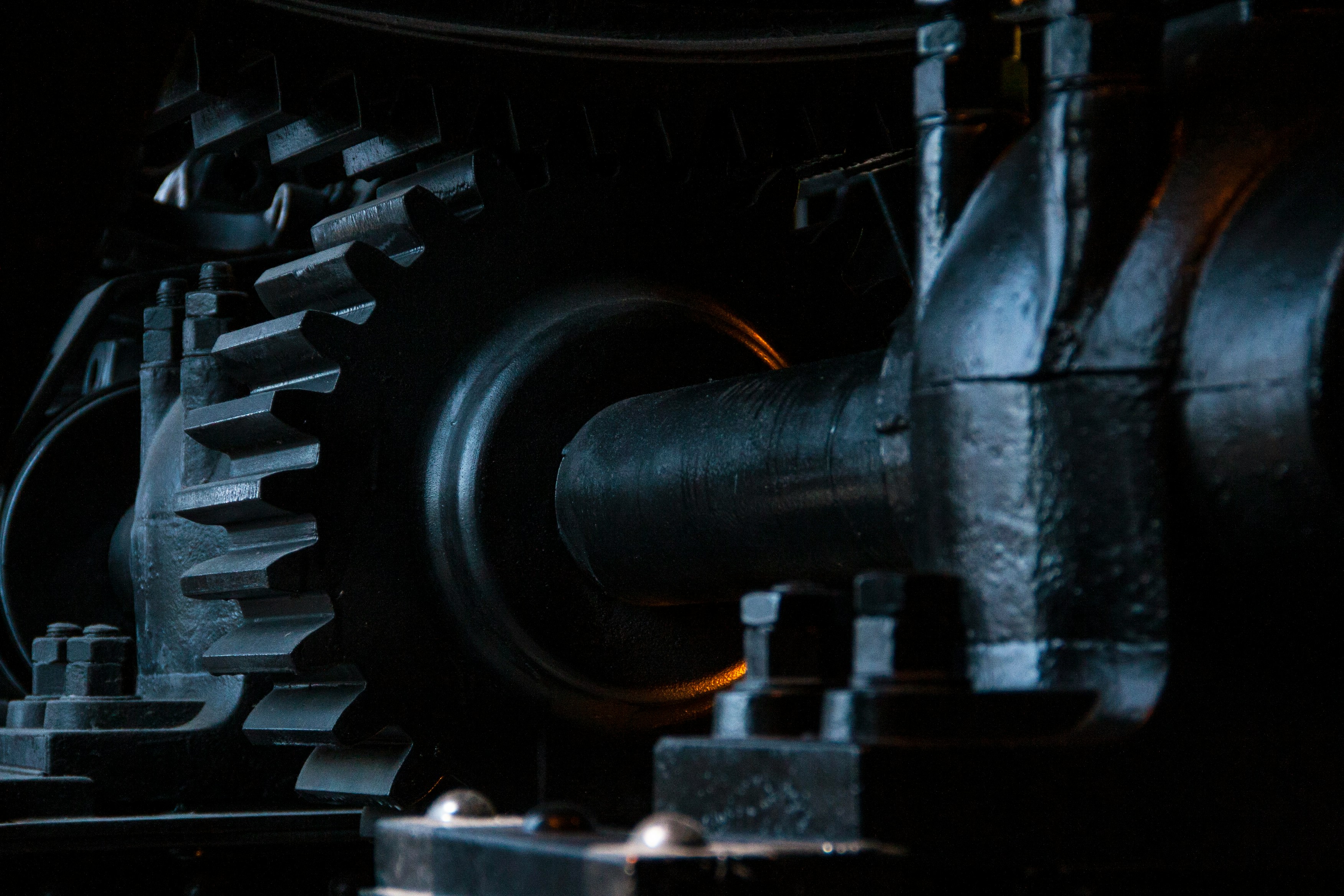

齒輪幫浦 異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

性能優化改善

Performance Improvement

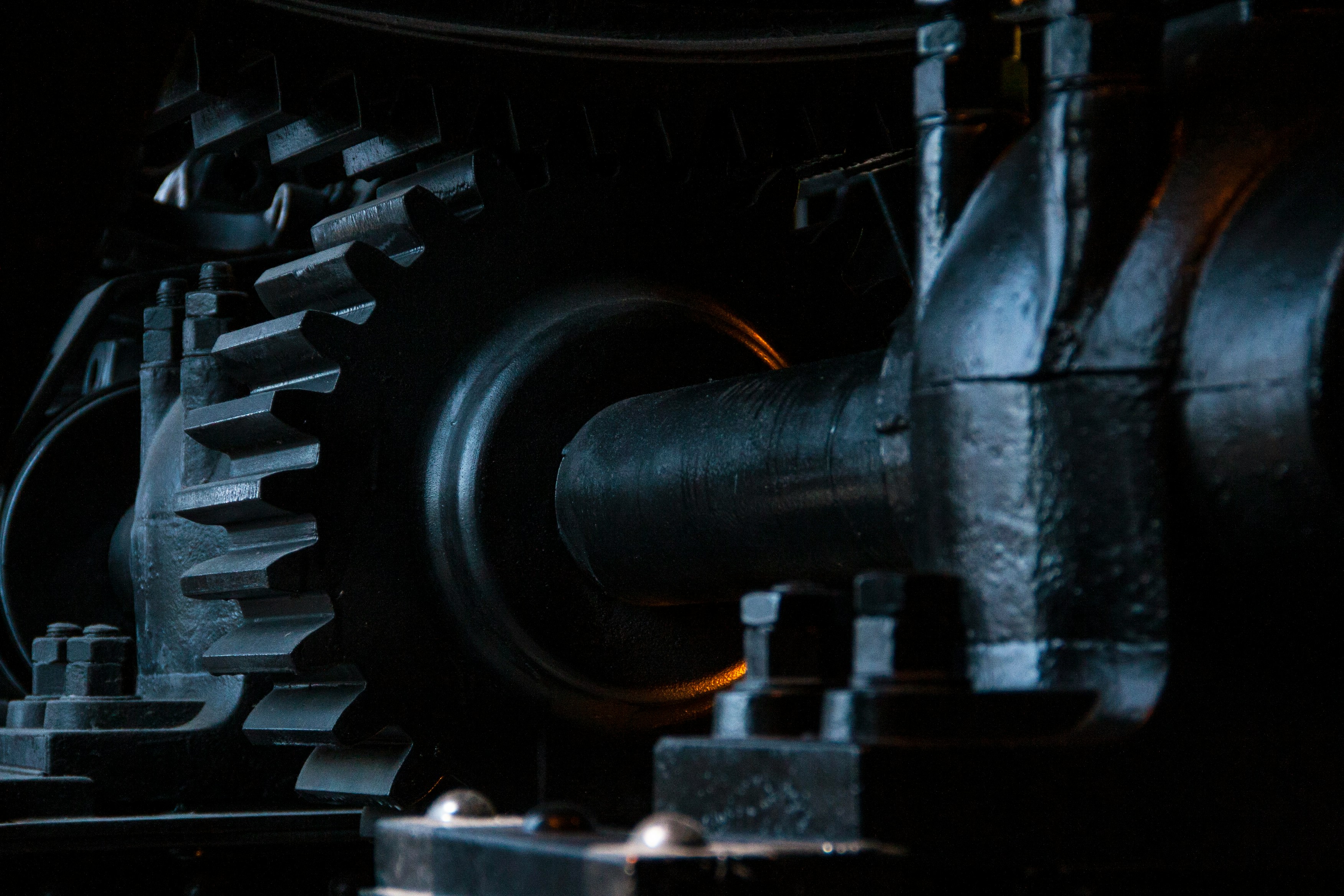

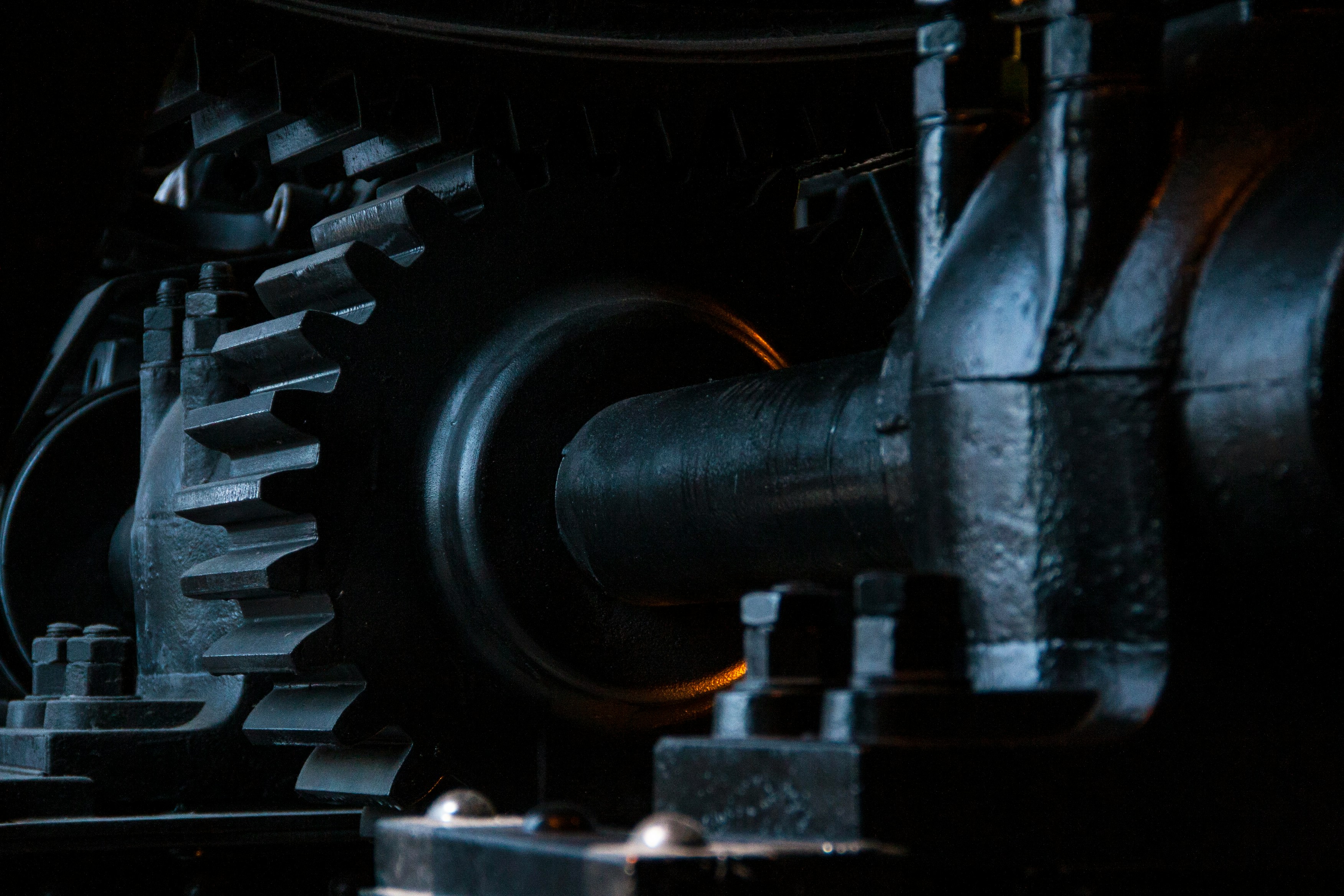

齒輪箱 模組 重新設計

Gearbox Module Redesign

針對長期異音與磨耗問題,重新推算模數、齒數與中心距,設計出更穩定的齒輪箱結構,有效提升傳動效率,並降低損耗風險。

Addressing long-term noise and wear issues, we recalculated module, tooth count, and center distance to design a more stable gearbox structure, effectively improving transmission efficiency and reducing wear risk.

面臨挑戰

Challenge

長期磨耗影響效率

Long-term wear affects efficiency

解決方案

Solution

優化結構參數

Optimize structural parameters

最終成果

Results

大幅降低維護需求

Significantly reduced maintenance requirements

新產品開發

Product Development

減速機 從零開發

Reducer Development from Scratch

客戶提供減速比概念需求,國星透過推算與模擬設計出行星減速機參數, 協助客戶將概念轉化為完整製造圖面並進行量產。

The client provided conceptual reduction ratio requirements. Guoxing calculated and simulated planetary reducer parameters, helping the client transform concepts into complete manufacturing drawings for mass production.

面臨挑戰

Challenge

從概念轉化為量產圖面

Need to transform concept into production drawings

解決方案

Solution

完整參數計算與圖面設計

Parameter calculation and design

最終成果

Results

成功量產

Successful mass production

設備異音問題

Equipment Noise Issues

齒輪幫浦 異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

設備異音問題

Equipment Noise Issues

齒輪幫浦 異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

性能優化改善

Performance Improvement

齒輪箱 模組 重新設計

Gearbox Module Redesign

針對長期異音與磨耗問題,重新推算模數、齒數與中心距,設計出更穩定的齒輪箱結構,有效提升傳動效率,並降低損耗風險。

Addressing long-term noise and wear issues, we recalculated module, tooth count, and center distance to design a more stable gearbox structure, effectively improving transmission efficiency and reducing wear risk.

面臨挑戰

Challenge

長期磨耗影響效率

Long-term wear affects efficiency

解決方案

Solution

優化結構參數

Optimize structural parameters

最終成果

Results

大幅降低維護需求

Significantly reduced maintenance requirements

新產品開發

Product Development

減速機 從零開發

Reducer Development from Scratch

客戶提供減速比概念需求,國星透過推算與模擬設計出行星減速機參數, 協助客戶將概念轉化為完整製造圖面並進行量產。

The client provided conceptual reduction ratio requirements. Guoxing calculated and simulated planetary reducer parameters, helping the client transform concepts into complete manufacturing drawings for mass production.

面臨挑戰

Challenge

從概念轉化為量產圖面

Need to transform concept into production drawings

解決方案

Solution

完整參數計算與圖面設計

Parameter calculation and design

最終成果

Results

成功量產

Successful mass production

設備異音問題

Equipment Noise Issues

齒輪幫浦 異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

性能優化改善

Performance Improvement

齒輪箱模組重新設計

Gearbox Module Redesign

針對長期異音與磨耗問題,重新推算模數、齒數與中心距,設計出更穩定的齒輪箱結構,有效提升傳動效率,並降低損耗風險。

Addressing long-term noise and wear issues, we recalculated module, tooth count, and center distance to design a more stable gearbox structure, effectively improving transmission efficiency and reducing wear risk.

面臨挑戰

Challenge

長期磨耗影響效率

Long-term wear affects efficiency

解決方案

Solution

優化結構參數

Optimize structural parameters

最終成果

Results

大幅降低維護需求

Significantly reduced maintenance requirements

新產品開發

Product Development

減速機從零開發

Reducer Development from Scratch

客戶提供減速比概念需求,國星透過推算與模擬設計出行星減速機參數, 協助客戶將概念轉化為完整製造圖面並進行量產。

The client provided conceptual reduction ratio requirements. Guoxing calculated and simulated planetary reducer parameters, helping the client transform concepts into complete manufacturing drawings for mass production.

面臨挑戰

Challenge

從概念轉化為量產圖面

Need to transform concept into production drawings

解決方案

Solution

完整參數計算與圖面設計

Parameter calculation and design

最終成果

Results

成功量產

Successful mass production

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

性能優化改善

Performance Improvement

齒輪箱模組重新設計

Gearbox Module Redesign

針對長期異音與磨耗問題,重新推算模數、齒數與中心距,設計出更穩定的齒輪箱結構,有效提升傳動效率,並降低損耗風險。

Addressing long-term noise and wear issues, we recalculated module, tooth count, and center distance to design a more stable gearbox structure, effectively improving transmission efficiency and reducing wear risk.

面臨挑戰

Challenge

長期磨耗影響效率

Long-term wear affects efficiency

解決方案

Solution

優化結構參數

Optimize structural parameters

最終成果

Results

大幅降低維護需求

Significantly reduced maintenance requirements

新產品開發

Product Development

減速機從零開發

Reducer Development from Scratch

客戶提供減速比概念需求,國星透過推算與模擬設計出行星減速機參數, 協助客戶將概念轉化為完整製造圖面並進行量產。

The client provided conceptual reduction ratio requirements. Guoxing calculated and simulated planetary reducer parameters, helping the client transform concepts into complete manufacturing drawings for mass production.

面臨挑戰

Challenge

從概念轉化為量產圖面

Need to transform concept into production drawings

解決方案

Solution

完整參數計算與圖面設計

Parameter calculation and design

最終成果

Results

成功量產

Successful mass production

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

幫浦運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

性能優化改善

Performance Improvement

齒輪箱模組重新設計

Gearbox Module Redesign

針對長期異音與磨耗問題,重新推算模數、齒數與中心距,設計出更穩定的齒輪箱結構,有效提升傳動效率,並降低損耗風險。

Addressing long-term noise and wear issues, we recalculated module, tooth count, and center distance to design a more stable gearbox structure, effectively improving transmission efficiency and reducing wear risk.

面臨挑戰

Challenge

長期磨耗影響效率

Long-term wear affects efficiency

解決方案

Solution

優化結構參數

Optimize structural parameters

最終成果

Results

大幅降低維護需求

Significantly reduced maintenance requirements

新產品開發

Product Development

減速機從零開發

Reducer Development from Scratch

客戶提供減速比概念需求,國星透過推算與模擬設計出行星減速機參數, 協助客戶將概念轉化為完整製造圖面並進行量產。

The client provided conceptual reduction ratio requirements. Guoxing calculated and simulated planetary reducer parameters, helping the client transform concepts into complete manufacturing drawings for mass production.

面臨挑戰

Challenge

從概念轉化為量產圖面

Need to transform concept into production drawings

解決方案

Solution

完整參數計算與圖面設計

Parameter calculation and design

最終成果

Results

成功量產

Successful mass production

設備異音問題

Equipment Noise Issues

齒輪幫浦異音改善

Gear Pump Noise Reduction

齒輪幫浦在運轉時出現異音與震動問題,我們從設計源頭分析問題,重新檢視齒輪配合與傳動路徑,並結合加工建議與組裝模擬,成功改善運轉流暢度,解決高頻異音問題。

The pump experienced noise and vibration issues during operation. We analyzed the problem from the design source, re-examined gear meshing and transmission paths, and combined manufacturing recommendations with assembly simulation to successfully improve operational smoothness and resolve high-frequency noise problems.

面臨挑戰

Challenge

幫浦運轉時出現異音與震動

Pump produces noise and vibration during operation

解決方案

Solution

重新設計傳動配置

Redesign transmission configuration

最終成果

Results

異音完全消除

Complete noise elimination

Services

Services

Services

我們提供從設計、優化到量產的完整技術支援

我們提供從設計、

優化到量產的

完整技術支援

我們提供從設計、優化到量產的

完整技術支援

We provide complete technical support

from design optimization to mass production.

We provide complete technical support from design optimization to mass production.

We provide complete technical support from design optimization to mass production.

1

技術設計支援

Design Optimization & Drawing Services

我們擅長從客戶提供的圖紙進行製造可行性評估,結合加工經驗與程式模擬,提出參數調整、齒形改善與結構優化建議,讓產品更具穩定性與量產潛力。

We excel at manufacturing feasibility assessment from client drawings, combining processing experience with simulation to provide parameter adjustments, gear profile improvements, and structural optimization suggestions for enhanced stability and production potential.

優化設計建議

Design optimization

提升產品性能與生產效率

Enhance performance and efficiency

製程可行性評估

Process feasibility assessment

降低開發風險

Reduce development risks

齒輪組推算

Gear calculation

精準對應設計需求

Precise design requirement matching

2

圖紙設計支援

Custom Drawing & Gear Configuration

3

客製化開發

Custom Component Development

4

製造整合與試作

Sample-to-Production Integration

1

技術設計支援

Design Optimization & Drawing Services

我們擅長從客戶提供的圖紙進行製造可行性評估,結合加工經驗與程式模擬,提出參數調整、齒形改善與結構優化建議,讓產品更具穩定性與量產潛力。

We excel at manufacturing feasibility assessment from client drawings, combining processing experience with simulation to provide parameter adjustments, gear profile improvements, and structural optimization suggestions for enhanced stability and production potential.

優化設計建議

Design optimization

提升產品性能與生產效率

Enhance performance and efficiency

製程可行性評估

Process feasibility assessment

降低開發風險

Reduce development risks

齒輪組推算

Gear calculation

精準對應設計需求

Precise design requirement matching

2

圖紙設計支援

Custom Drawing & Gear Configuration

3

客製化開發

Custom Component Development

4

製造整合與試作

Sample-to-Production Integration

1

技術設計支援

Design Optimization & Drawing Services

我們擅長從客戶提供的圖紙進行製造可行性評估,結合加工經驗與程式模擬,提出參數調整、齒形改善與結構優化建議,讓產品更具穩定性與量產潛力。

We excel at manufacturing feasibility assessment from client drawings, combining processing experience with simulation to provide parameter adjustments, gear profile improvements, and structural optimization suggestions for enhanced stability and production potential.

優化設計建議

Design optimization

提升產品性能與生產效率

Enhance performance and efficiency

製程可行性評估

Process feasibility assessment

降低開發風險

Reduce development risks

齒輪組推算

Gear calculation

精準對應設計需求

Precise design requirement matching

2

圖紙設計支援

Custom Drawing & Gear Configuration

3

客製化開發

Custom Component Development

4

製造整合與試作

Sample-to-Production Integration

Applications

Applications

Applications

憑藉深厚製造經驗,

提供客製化解決方案。

憑藉深厚製造經驗,為多產業提供客製化解決方案

憑藉深厚製造經驗,

提供客製化解決方案

With extensive manufacturing experience, providing customized industry solutions.

With extensive manufacturing experience,

providing customized industry solutions.

從汽車傳動系統到航太精密機構、電動工具到機械手臂關節,我們的技術應用遍及各個工業領域。

每個產業都有獨特的精密度要求與使用環境,我們運用專業知識與製造經驗,為各領域提供最適合的零件設計與製造方案。

從汽車傳動系統到航太精密機構、電動工具到機械手臂關節,我們的技術應用遍及各個工業領域。

每個產業都有獨特的精密度要求與使用環境,我們運用專業知識與製造經驗,為各領域提供最適合的零件設計與製造方案。

從汽車傳動系統到航太精密機構,電動工具到機械手臂關節,

我們的技術應用遍及各個工業領域。

每個產業都有獨特的精密度要求與使用環境,

我們運用專業知識與製造經驗,

為各領域提供最適合的零件設計與製造方案。

From automotive drivetrain systems to aerospace precision mechanisms, from power tools to robotic arm joints,

our technology applications span across various industrial sectors.

Each industry has unique precision requirements and operating environments. We leverage professional knowledge and manufacturing experience to provide the most suitable component design and manufacturing solutions for each field.

From automotive drivetrain systems to aerospace precision mechanisms, from power tools to robotic arm joints, our technology applications span across various industrial sectors.

Each industry has unique precision requirements and operating environments. We leverage professional knowledge and manufacturing experience to provide the most suitable component design and manufacturing solutions for each field.

We believe great design comes from deeply understanding client needs and manufacturing realities. With extensive manufacturing experience,

we combine technical expertise with design innovation to become your trusted development partner,

delivering complete solutions from concept to mass production.

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

汽車

Automotive

齒輪

Gears

軸承

Bearings

傳動系統

Drive Systems

航太

Aerospace

驅動齒輪

Drive Gears

控制元件

Control Elements

精密軸承

Precision Bearings

電動工具

Power Tools

減速機

Reducers

行星齒輪

Planetary Gears

扭力機構

Torque Mechanisms

高階腳踏車

Bicycles

花鼓

Hubs

棘輪

Ratchets

變速系統

Shifting Systems

機械手臂

Robotic Arms

減速機

Reducers

伺服齒輪

Servo Gears

關節軸承

Joint Bearings

自動化設備

Automation Equipment

導軌

Linear Guides

傳動軸

Drive Shafts

精密定位件

Actuators

Contact

Contact

Contact

聯絡我們

聯絡我們

Get in touch

Get in touch

如有諮詢需求或想進一步討論您的想法,歡迎聯繫我們。

For any consultation needs or to further discuss your ideas,

please feel free to contact us.

地址

Address

桃園市新屋區清華一街230號

No. 230, Qinghua 1st St.,Xinwu Dist.,Taoyuan City 327, Taiwan (R.O.C.)

信箱

info@glonius.com

電話

Tel

03-4972328

地址

Address

桃園市新屋區清華一街230號

No. 230, Qinghua 1st St.,Xinwu Dist.,Taoyuan City 327, Taiwan (R.O.C.)

信箱

info@glonius.com

電話

Tel

03-4972328

Our partner

Our partner

Our partner

我們的製造夥伴

我們的製造夥伴

Our Manufacturing Partner

Our Manufacturing Partner

Our Manufacturing Partner

禾致動力科技有限公司

禾致動力科技有限公司

Global Gear Industry Co.,Ltd.

Global Gear

Industry Co.,Ltd.

國星的子公司「禾致動力科技有限公司」擁有近60年精密齒輪製造經驗,為國星提供深厚的技術底蘊與製造專業。

國星的子公司「禾致動力科技有限公司」擁有近60年精密齒輪製造經驗,

為國星提供深厚的技術底蘊與製造專業。

Our subsidiary "Global Gear Industry Co.,Ltd." has nearly 60 years of precision gear manufacturing experience,

providing Glonius with deep technical foundation and manufacturing expertise.